Pressure Test Hvac System

Pressure test hvac system. The testing is quite simple and quick to complete usually being carried out before other commissioning. The testing is usually completed after any installation or modification works. SOUND LEVEL TEST HVAC QUALIFICATION.

The emphasis is on the process of pressure testing rather than on pressure testing safety. For pressure testing you can pressurize through either side of the piping or both sides. A hydrostatic test is performed by.

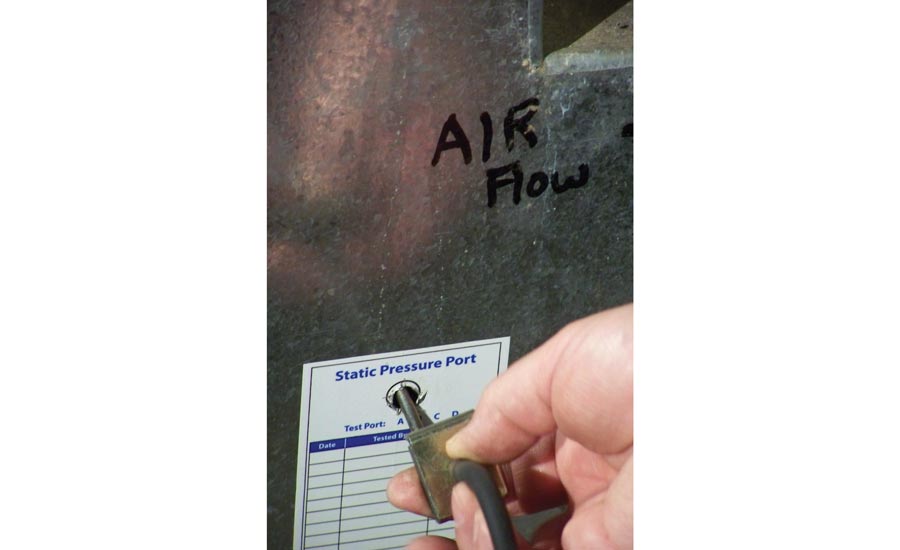

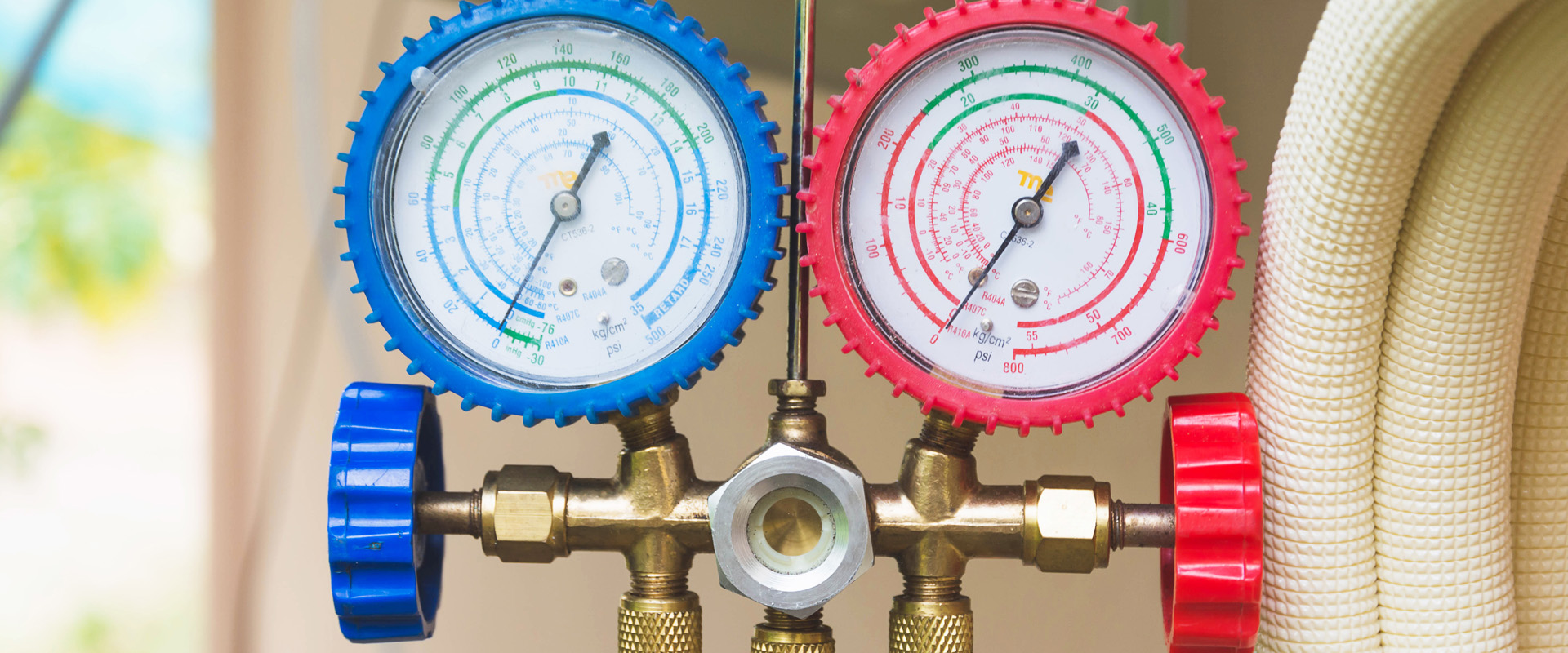

In this HVAC Video I go over how to Pressure Test Refrigeration Lines for an Air Conditioner. Identifying a static pressure issue before it causes a system failure will save your customers a lot of hassle and money. Pressure Dependent Leaks PDL are leaks that can only be detected as the pressure is built.

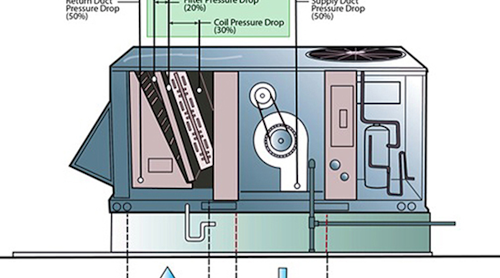

Top 7 Crucial Tips for Pressure Testing HVAC Systems. Determine total external static pressure and system pressure drops. There are two methods for pressure tests.

Static pressure is also known as system air resistance and it is essentially a measure of the resistance to airflow that occurs in the HVAC system. Ducts shall be pressure tested to determine air leakage by either of the following. To bridge the gap this publication focuses on safe work.

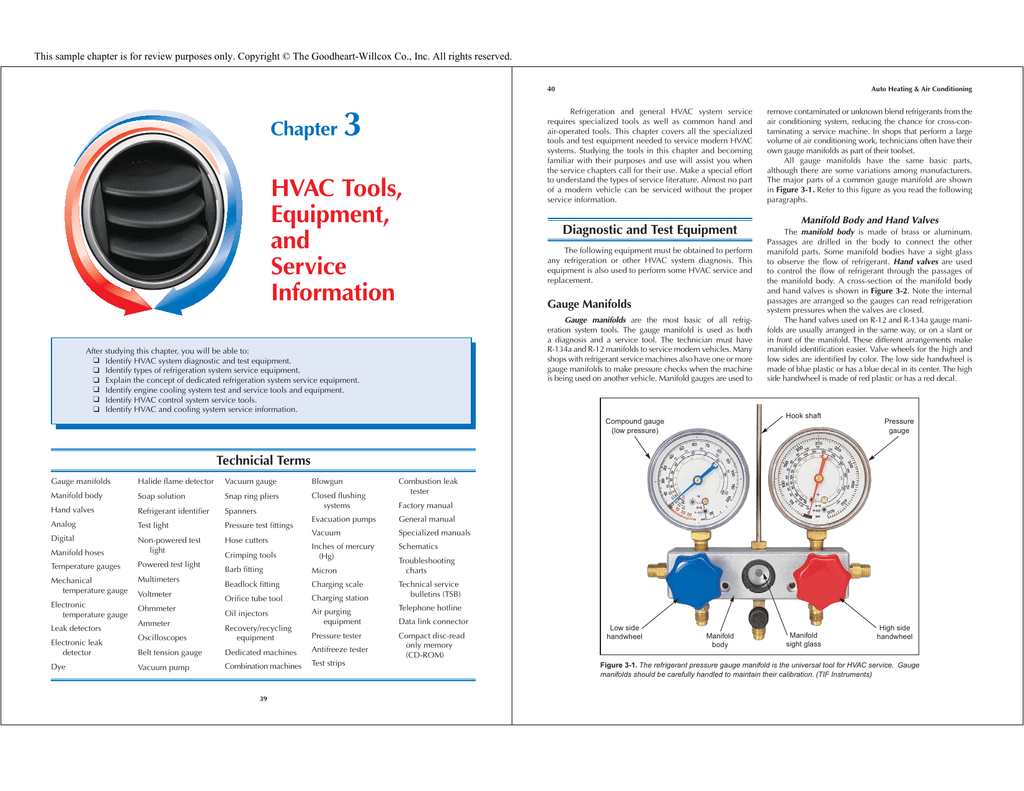

Refrigeration and Air Conditioning Technology by Whitma n instructs you to perform a standing pressure test by filling a new system with dry nitrogen up to the operating pressure of the system. It does not instruct you to pull a vacuum first before introducing the nitrogen. In This HVAC Video I go over how to Accurately Pressure Test an Air Conditioner.

The static pressure in ductwork is indicative of what condition the ducts are in and can help you diagnose common problems and inform you on. Helium or dry air is acceptable.

Pressure testing is a very small part of each of these standards.

In pressure-testing you use a moisture-free inert gas to pressurize the AC system. Do not use a. In this HVAC Video I go over how to Pressure Test Refrigeration Lines for an Air Conditioner. High pressures are used so all non-essential personal should be evacuated from the area. I show where to Find the Max Design Pressure how long to hold. Symptoms of a static pressure issue include excessive noise hot and cold spots in the home and even equipment failure. 25 Pa across the system including manufacturers air handler enclosure All registers taped or otherwise sealed. So to reiterate getting the right pressure is important to ensure that any system works as required when in heating or cooling but checking this these days is much quicker and much more straightforward than it used to be and there is no longer any need to break. Nitrogen is used to pressurize low sides to 150 psi and high sides to 450 psi.

A pressure test is required for a new pressure system before use or an existing pressure system after repair or alteration. Just dont exceed the max pressure of the coil. Pressure testing is hazardous and should be carried out carefully. The test pressure shall be at least 11 and shall not exceed 13 times the design pressure of any component in the system. There are two methods for pressure tests. What is positive air pressure. In This HVAC Video I go over how to Accurately Pressure Test an Air Conditioner.

Post a Comment for "Pressure Test Hvac System"